The Mantra for Millennium Management

Strategic Business Solutions with Six Sigma

Dr.R.D.Mishra

Director, Greater Noida Productivity Council

Six Sigma is a disciplined, statistical-based, data-driven approach and continuous improvement methodology for eliminating defects in a product, process or service. … Six Sigma can also be thought of as a measure of process performance, with Six Sigma being the goal, based on the defects per million.

Background :

In the world of today’s business, a company’s survival is totally dependent on 3 Cs: i.e. Customer, Change and Competition. The progressive organization have been undertaking various initiatives since last five decades such as Financial Analysis in 1960s, Competitive Analysis in 1970s, Performance Benchmarking in 1980s, Process/Activity Benchmarking in 1990s and off late it is Six-Sigma Strategy for breakthrough improvement for sustainable competitive advantage. Probably all of these approaches have their relevance and importance specific to the business environment prevalent in that time. However, the present day requirement calls for more proactive approach for “customer lock-in” which is deployed by incorporating leading process performance measure rather than lagging performance measures. The leading measures are important in the sense that it facilitates the management in taking preventive and corrective decision-making and thereby fulfills the customer requirement at lower quality cost.

The second most important feature of six sigma strategy is that it defines, analyses and synthesizes every activity in an organization with process orientation and all the process performance parameters are compared under one single umbrella of six sigma so that improvement and control are better measured, and maintained.

Six Sigma is a business strategy first advocated by Motorola in the early 1990s and recent success stories of General Electric, Sony, Allied Signals have captured the attention of all most all Fortune 500 companies and many progressive units in India also. This very strategy involves the use of statistical tools within a structured methodology for gaining knowledge needed to achieve faster, better and less expensive products and services than the competitor. The repeated and structured application of this strategy on project after project, where the projects are based on key business issues, is what drives money to bottom line, resulting in increased profit margins and impressive return on investment from human resource development namely six sigma training.

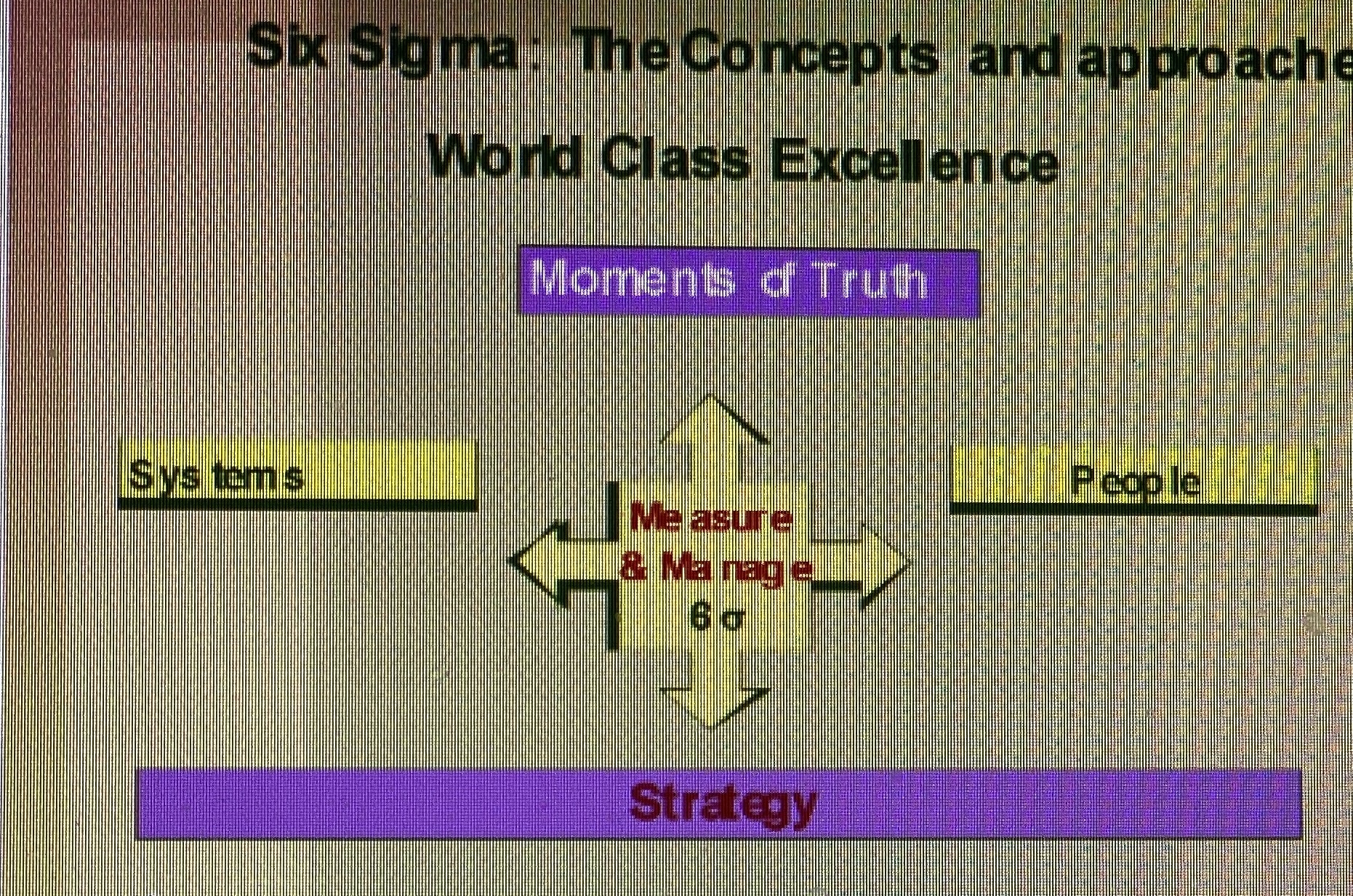

Six Sigma : The Concepts and approaches

Six sigma applies in all areas of business, for instance it is applicable in insurance brokerage services, hospital care, bulk chemicals transportation, training services, commodity fasteners, computer chips, software, gas turbine, car, aero planes. Safety and everything we use to generate business and income.

The six sigma approach starts with well laid out and communicated business strategy that focuses on :

- People and People Development

- Processes and Systems

- Six Sigma approach to projects

The result of successful six sigma application is the melding of the business organizations focus, through strategy, binding the synergy of people with process that aims at world class excellence in the areas that are critical to the organization’s customers. As we know world class excellence is defined by the customer only, keeping this very line in mind the organization shall set their business objective. Based on this the overall business unit strategy may be formulated and developed. This may have 6-9 key performance area at any one time and as we go down the organization our day to day activity links with at least one of these 6-9 key performance areas. The six sigma improvements come in two different ways

- To improve the systems and processes that is in use by deploying process improvement tools.

- Development of capability of people as individuals in teams and as an organization.

Six Sigma is a philosophy or understanding that defects cost money. The best way to make more profit is to eliminate defects. The organization believes in this and practices has a lower cost of quality and more likely to have higher customer loyalty as well as higher profit.

Six Sigma is a performance tool and it implies that product and services that are produced perform at level where chances of defects are less than 3.4 ppm. (i.e. 3.4 in a million opportunity). The 3.4 ppm defect rate is not what we find if we look at normal distribution table considering both trails. Actually statistical process control which has been long used is normally conducted to keep performance within three sigma variation i.e. 66810 defects per million opportunities, keeping the allowance of 1.5 sigma natural shift usual process average and 1.5 standard deviation shift of mean produces no more than 3.4 ppm defectives.

The Six Sigma is a methodology for working on projects based on phases :

- Strategy

- Define

- Measure

- Analyze

- Improve

- Control

Personal. Team and Organizational Growth

| Define | Scope, boundaries, expected results in balanced scorecard areas, high level process map, resources, time |

| Measure | Align Strategic Plan, Value, Scope, Document Process, Capability, Measurements, Performance |

| Analyze | FTA, FMEA, Root Cause, Test Means & Variances, Cause and Effect, Pareto, Task Force, Cycle Time, Reliability, Confirm Value |

| Improve | Reduce Cycle Time, Improve Reliability, DOE, Reduce Complexity, Management of Change, Project Management |

| Control | Control Chart, Audits, New Capability, Documentation, Share/Education, Total Value |

First, strategy of organization is developed, then progress is made in process/system improvement and people development. It uses a project approach to make improvement in critical areas and SDMAIC are the basic steps involved.

Six Sigma is not a simple process improvement tool, well the tools and techniques are always beneficial for process improvement but that shall be in tune with the business strategy and development of people. Six Sigma focuses on Customer Critical Criteria and World Class Performance with process improvements, people development and a sound business strategy to yield results.

Finally to conclude the six sigma strategy, the following 5W, 1H is given for ready reference :

Why Business Strategy for World Class Excellence

Where Customer Critical Criteria

What Defect Reduction

How Projects DMAIC, People Development, Tools

Who Black Belts, Green Belts, Team Members

When Usually 3-9 months per project